Process Optimization Part 4

Welcome to the final part in our series on process improvement.

Over the past few weeks we have seen some tools that can help boost productivity to achieve greater customer satisfaction for example:

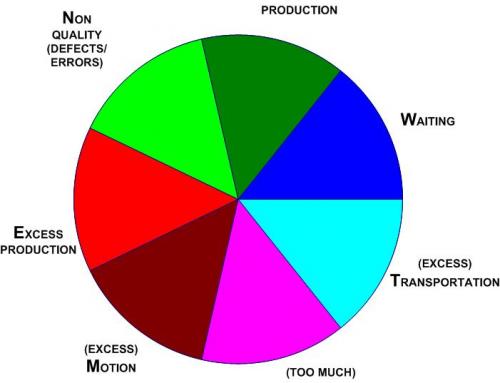

CTQ , SIPOC, MUDA types of waste, Pareto charts, Kano diagrams, RUMBA and how to mitigate risk.

Today lets tackle how to solve known problems.

5 WHYs, to get to ROOT CAUSE

To solve a problem efficiently, one first needs to understand what is really causing it in the first place.

The FIVE WHYs is 1 way to invest time and resources in problem prevention.

When trying to understand root cause, ask WHY 5 times systematically to reveal the “real” (root root root root root) cause, that otherwise may remain elusive behind more visible symptoms.

Often, at that deep level of root cause, human error is revealed, that might have been avoided through earlier training or improved documentation.

In such case, the answer is to revisit documentation or training, but avoiding laying blame at all costs!

5 WHY Analysis

HOW YOU CAN USE THIS? Understanding true root cause pinpoints which process to improve, to avoid recurrence.

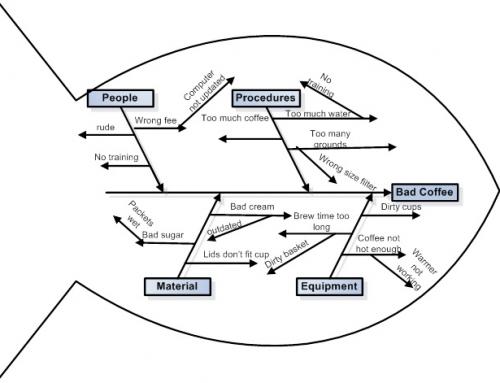

ISHIKAWA

Ishikawa or fishbone diagrams are useful to show cause and effect to help reveal root cause.

It is best done as a brainstorming session, when participants gather in a room around a white board and repeatedly ask the “Why did THAT happen” question.

In the first round, each suggestion is recorded as a category, a branch from the main backbone.

In subsequent rounds of asking “but WHY did THAT happen?”, sub branches, representing sub causes, appear coming off the previous set of branches.

HOW YOU CAN USE THIS? the Ishikawa diagram is a simple, visual way to map many inputs to potential factors influencing key outputs. In other words, the fish bones reveal the root causes of a symptom, which can then be prioritized, to mitigate potential future risk.

HOLACRACY

To round out our discussion, let us look at how applying HOLACRACY may help your organization prosper.

Breaking down the term holacracy:

- -cracy is governance

- holon is a whole that is part of a larger whole

- holarchy is the connection between holons.

For example:

The human body, where each cell is a holon, a self-contained complete entity AND a part of a larger whole (organ), with each organ itself a self-contained complete entity AND also part of a bigger whole (body); this series of nested holons is the holarchy.

Holacracy is governance of and by the organizational holarchy, where the component holarchies simultaneously respect autonomy while facilitating self-organization at every internal level. An organization’s basic holons are the roles that make up the organization’s functions. An easy on-ramp to Holacracy is to replace some terminology:

Replace problem with tension, a more positive word implying a gap between current reality and sensed potential opportunity.

Replace solutions with processing, replacing the idea of a fixed outcome with a more open-ended journey of continuous improvement.

Later replace tension with proposal, enabling a more approachable way to initiate discussion for improvement to a situation.

Replace any objections with, everyone see any reason why my proposal isn’t safe enough to try, knowing we can revisit it? to simplify decision making and save time by removing fear of risk and feelings of being threatened.

Replace specific people/names with roles when assigning actions, reducing anxiety, facilitating easier adoption.

HOW YOU CAN USE THIS? Holacracy is a social approach for running an organization, whereby authority is redistributed to roles, a very powerful concept in larger organizations, to optimize agility and flexibility.

FINAL RECAP

As we come to the end of our journey on process improvement, I’d like to thank you for your time and interest.

Hopefully from this set of tips, you will pick at least 1, to apply immediately, to improve your organization’s efficiency to better equip you to understand your customers’ requirements then exceed their expectations.

From reducing waste, to understanding root cause, from mitigating risk, to prioritizing what to fix, there is something for everyone.

Thanks again for this opportunity to share with you.

Until we meet again, this is Fay Rakoff, Consultant, Operational Efficiency, with Boardroom Metrics .

REFERENCES

Brue, G. (2015). Six Sigma for Managers Second Edition. United States: McGraw-Hill Education.

George, M. L., & Rowlands, D., & Price, M., & Maxey, J. (2005). Lean Six Sigma Pocket Toolbook. United States: George Group

Gygi, C., & DeCarlo, N., & Williams, B. (2005). Six Sigma for Dummies. Indiana: Wiley Publishing, Inc.

Gygi, C., & DeCarlo, N., & Williams, B. (2012). Six Sigma for Dummies 2nd Edition. New Jersey: John Wiley & Sons, Inc.

Kallet, M. (2014). Think Smarter. New Jersey: John Wiley & Sons, Inc.

KellyLawless. (2013). Fishbone BadCoffeeExample.jpg (Own work).

Pande, P. S., & Neuman, R. P., & Cavanaugh, R. R. (2014). The Six Sigma Way Second Edition. United States: McGraw-Hill Education.

Ries, E. (2011). The Lean Startup. New York: Crown Business.

Robertson, B. J. (2015). Holacracy. New York: Henry Holt and Company, LLC.

Thompson, J. (1997). The Lean Office. Canada: Productive Publications

Leave A Comment