Increasing Sales isn’t the Only way to Increase the Bottom Line

Okay, so you have a good product, the sales are there, and you have a good group of employees. Everything is in place. Now what? Have you considered improving your business processes?

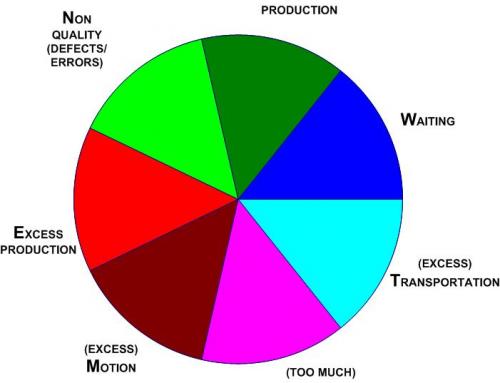

What does improving your business processes have to do with increasing profitability? Improving business processes is directly related to increases in quality. Did you know that 20% to 40% of sales revenue could be lost due to poor quality? Losses due to quality are not always apparent. The costs can be hidden in lost sales, warranties, increased production costs, labour, and materials. The costs don’t end there, on the production floor, they often carry-forward to the jobs that are performed in the office accounting for costs, analyzing data, purchase of additional materials, delivery costs, etc.

What does improving your business processes have to do with increasing profitability? Improving business processes is directly related to increases in quality. Did you know that 20% to 40% of sales revenue could be lost due to poor quality? Losses due to quality are not always apparent. The costs can be hidden in lost sales, warranties, increased production costs, labour, and materials. The costs don’t end there, on the production floor, they often carry-forward to the jobs that are performed in the office accounting for costs, analyzing data, purchase of additional materials, delivery costs, etc.

Consider a quality issue where the customer returns a product or brings it in for warranty. Costs have now increased to handle the return and/or warranty department costs. There is paperwork, labour, material, phones, office space and many others incidentals that decrease the bottom-line. If you are lucky, the customer will continue to purchase products from you, but there is also a chance that they will go elsewhere.

Every process/procedure has a quality component, and every time quality becomes an issue, it costs companies money whether it is directly attributed to purchases or increased man-hours.

Many will say that “Quality” is arbitrary and subjective, that’s true, but the quality of a product is directly related to customer satisfaction. The greater the customer satisfaction – the greater your sales.

W. Edward Deming believed that quality could be controlled through the management and improvement of processes. Deming was an American Statistician and Professor who is best known for his contribution to Japan’s industrial revitalization in the 1950’s. Deming gave several lectures throughout Japan relating quality to increased profitability and market share. Deming carried his philosophies to the U.S. and in the 1980’s, helped Ford Company turn a $3 billion loss around, becoming the most profitable company in the auto industry in 1986. Deming’s philosophy has been used the world over and inspired many quality-management tools used today, such as Six Sigma and ISO.

Each quality-management tool is based on developing and maintaining consistent levels of performance through the development of standardized processes. DMAIC is just one of the project methodologies used by Six Sigma, and is defined as Define, Measure, Analyze, Improve, and Control.

These five simple words when put into action, can turn companies around and turn losses into profitability. Is it a simple process? No, it takes time and commitment by management and employees. If it were simple, all organizations would run perfectly.

See my previous blogs for more insight on Improving Your Business Processes

Leave A Comment